Welcome to Precision

A small business located in Shelley, Idaho, dedicated to quality sharpening services for individuals and businesses across America.

A small business located in Shelley, Idaho, dedicated to quality sharpening services for individuals and businesses across America.

Scissors can be sharpened on one of several machines. Beveled edge scissors are sharpened on a special machine called a “Twice as Sharp”. This machine has a fixture that can be set to the angle of the beveled edge of the scissors. These scissors can be sharpened relatively easily without taking them apart. Most grooming shears have a beveled edge.

Veterinary scissors that have carbide inserts are sharpened with a diamond stone to ensure a good clean cutting edge.

Higher-end Japanese-style shears have a honed edge. These shears are much more involved to sharpen and are usually made of a higher quality steel. They are sharpened on a flat hone and must be disassembled. Each blade is sharpened independently by hand and reassembled. Honed shears do cost more to sharpen than beveled edge shears but are much sharper and should be used primarily for finish scissoring.

All clipper blades are sharpened by the same process used at the factory. Most blades need to be hollow ground, and we accomplish this by sharpening on equipment that hones a precision hollow grind the same as the factory does.

All blade parts are organized in aluminum trays to keep the parts of each blade together and prevent mixing parts.

After the blades are disassembled, cleaned, and blown off, they are put on the clipper hone and sharpened until the entire cutting surface is honed to a new cutting edge. This usually removes about 1 to 2 thousandths of an inch (.001 to .002) of material, which is less than the thickness of a human hair. After the blades come off the hone they are blown clean again. Then, the blades are demagnetized, washed in a degreaser cleaner, and blown dry with compressed air. At this point, each blade is oiled and reassembled, the top cutter is aligned, and the spring tension is checked. Each blade is tested with a special test string, which is the same test used in the factory. If any blades have been identified as problem blades, they are tested on rabbit fur. If they can cut rabbit fur, they will cut most any hair.

Blade parts are replaced as needed. This includes springs, guides, sockets, screws, and even top cutters. If a blade has a broken tooth on the comb, it cannot be sharpened because it presents a hazard to the animal or person. Oster #40 blades can have the comb (bottom blade) replaced. All other sizes do not have replacement combs. You can use Oster combs with Andis blades. Please feel free to ask questions about blades and parts replacement.

The word "scissor" comes from the Latin word "cisoria," meaning a cutting instrument, and the spelling is due to confusion with the Latin word "scissor," a form of the verb "scinder," meaning “to cut.” The word appears in Old French between 842-1300 A.D. as "cisoires," from which the Modern French word "Ciseaux" derives. In late Middle English, about 1400 A.D., there is found reference to "sisours" and "cysowres."

The word "shears" has quite a different derivation, originating from the Germanic/Teutonic root "Sker," which later changed to "Skeresa." In Old English, the word became "Scear." Currently in German, the word is "schere.”

Today's modern dictionaries define a scissor as "a cutting implement consisting of two blades joined by a swivel pin that allows the cutting edges to be opened and closed," while a shear is defined as "a pair of scissors" and "any of various implements or machines that cut with a scissor like action, often used in the plural".

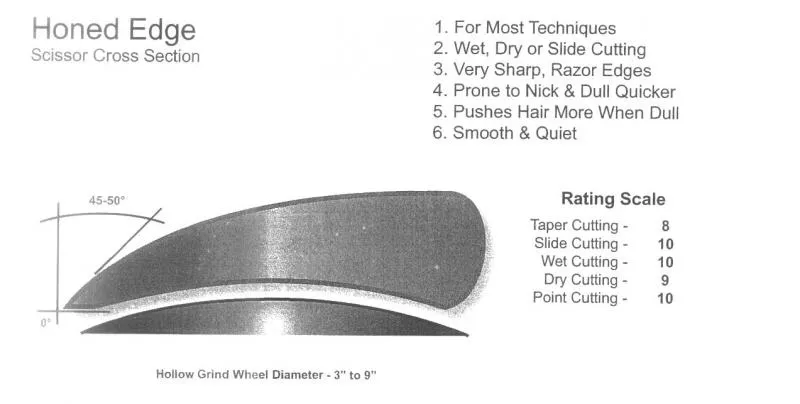

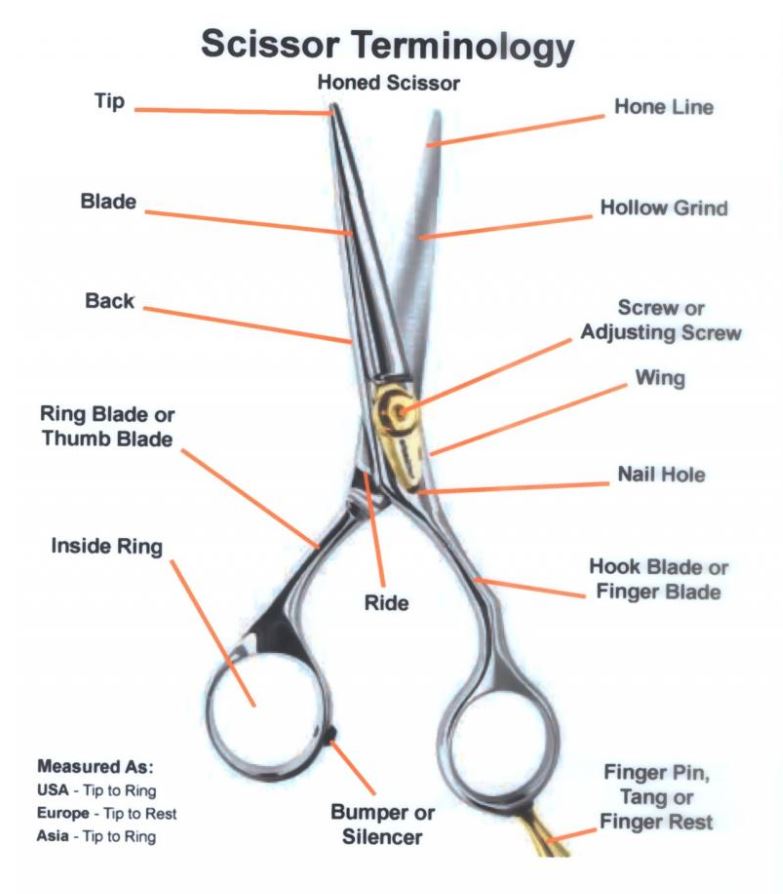

Japanese-style scissors have particularly sharp edges that taper to a point called a convex edge or honed scissor. These edges are very thin and sharp allowing the user to use all cutting techniques, including slide cuts, wisping, etc. Because the edges are so sharp, they would rub themselves dull on the hollow side of the edge. To prevent this, a hone line is ground in the hollow along the edge. The hone line is the thin flat line you see on the hollow side of the edge that runs from the tip of the scissor to the back. This gives the scissor a smooth and quiet run. Without the hone line, the scissor would run hard and loud.

The run is the feel and function of opening and closing a scissor. If a scissor sharpener does not sharpen and re-hone your scissor correctly, the scissor will never feel like it did when it was new. When sharpened correctly, the scissor often feels and cuts better than when it was new!

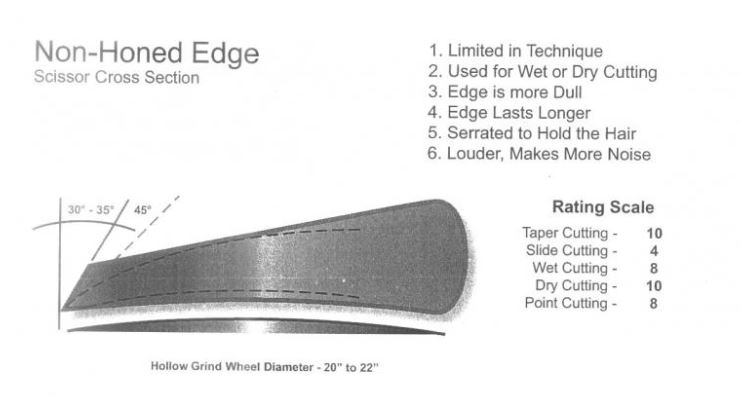

A German scissor has flatter edges than a convex scissor. This is called a sword or bevel edge. Bevel edges are not as angled as a convexed edges, thus requiring one or both edges to be serrated or corrugated. Serrations are fine lines or teeth ground into the edge of one blade. The serration holds the hair, and prevents it from being pushed forward.

Because of its particularly sharp edges, the Japanese scissor (convex edge) cuts through hair smoothly and efficiently, with less force. The convex scissor is constructed for slide cutting or wisping. It runs smoothly, quietly, and lightly. However, it has the tendency to nick and dull faster than a bevel edge scissor and the tendency to push the hair more than a serrated bevel edge scissor.

The German scissor (bevel edge) is very durable. It holds the hair well and does not push hair forward. It is the scissor of choice for blunt and layer cutting, dry cutting, and for cutting synthetic and coarse hair. However, due to the serration, it is unable to slide cut. It also runs louder and rougher than a convex scissor.

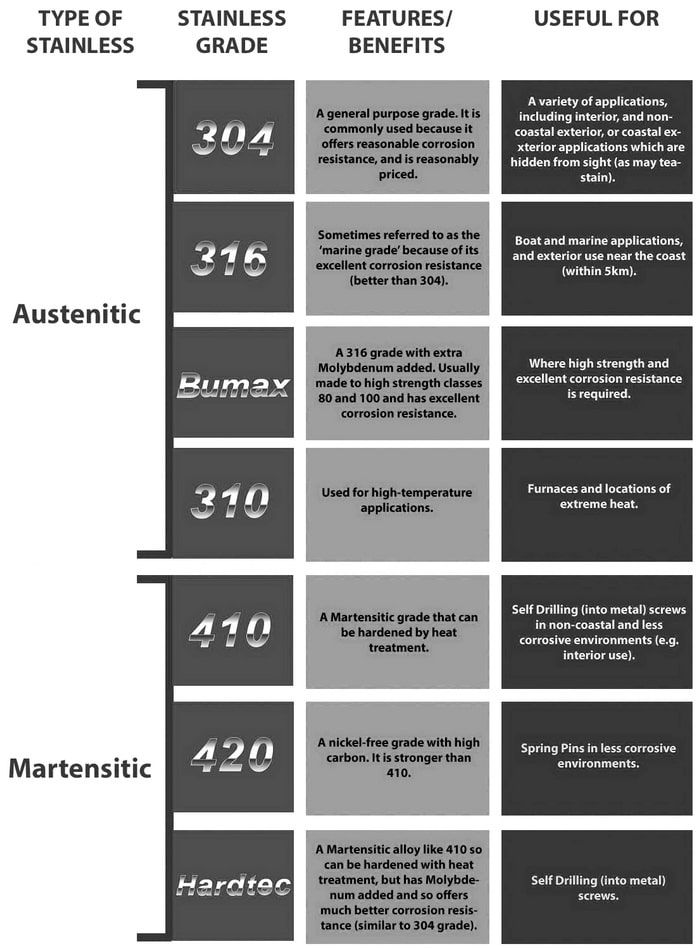

STEEL - What type of steel alloy the scissor is made from: What grade of steel is it? 300 series, 400 series, etc. This is the general metallurgical composition of the scissor.

PROCESS - The processing of this steel: Is it forged, cast, or sintered metal. Was it heat treated correctly, ice-tempered, etc.? Even the best steel can be useless in a scissor when processed poorly.

MANUFACTURE - The manufacture of the scissor: Is it convexed or beveled? Is it hollow ground? If so, is the rake angle correct, etc.?

In the world of blades, the word "ice" is so popular that a lot of regular carbon steel scissors and shears claim to be ice-tempered, which does not technically make sense. Some even think "ice" is a brand name. The important thing to remember is that ice tempering is only beneficial on stainless steel.

In a simplified form, stainless steel is regular steel with chromium added to make the steel more rust resistant, thus "stainless" steel. The disadvantage of the high content of chromium in stainless steel is that the cutting edge dulls quicker. To overcome this, the steel is subjected to freezing temperatures to optimize the steel structure for hardness.

This is how it works: To make steel hard, it has to be heat treated. With stainless steel, that means heating the steel above 2000 degrees Fahrenheit. At that temperature the structure of the material is at its optimum. To preserve this structure, the steel is cooled rapidly (quenched) and tempered at about 450 degrees Fahrenheit. Now the steel has decent hardness and flexibility in the tool, but the chromium in the steel will not permit a long lasting cutting edge. To make the cutting edge last longer, the steel is subjected to around 120 degrees below zero; in other words, "ice-tempered". Without a steel analysis, it is virtually impossible to prove or disprove if ice tempering was done, without a steel analysis. The only proof is how many cuts the scissor or shear can make before it dulls.

For drop forged shears, pieces of steel are heated up red hot and put in a die, which is a mold that can withstand substantial pressure and looks somewhat like a cake pan in the shape of the shear or tool. Half of the form is fastened to a large anvil; the other half of the die is attached to the ram which acts like a hammer. The ram comes down on the steel, forging the pliable steel into the die and giving the steel the form of the future shear. These drop hammers are up to 20 feet high, standing on a 10-foot deep foundation. The ram can weigh 1000 lbs. or more. Because of variances in dimensions of the shears, some of the hot steel is being squeezed out of the die cavity. This creates a large burr which is cut off under heavy presses. The still hot-shear forgings are then cooled under controlled conditions to eliminate internal stress. They are then tempered and trimmed.

Molten metal poured into a mold that is formed to the desired shape is a cast shear. The casting process leaves the molecules of the metal in such a configuration that the metal becomes brittle and can be broken if dropped or if the sharpener tries to re-set the blade by bending. Cast scissors are harder and more durable than forged scissors but can break easily.

Most less expensive shears are blanked out. Strips of steel are cut out in the form of a shear, like rolled cookie dough is shaped with cookie cutters. The cheaper version of the "blanked" shears are then ground into shape. For a better quality, the cut out "blanks" are put into a powerful press and the blade is squeezed into shape, thereby making the steel near the edge compressed and creating a longer lasting cutting edge. This means that not all cheap shears are equally cheap. Drop forged tools and shears are far superior to blanked ones. The material flow of the hot metal being forged and pounded into the cavity gives the steel a much denser structure, better quality and ultimately longer life.

Cobalt scissors come in two types: Forged steel and powder or sintered metal. Powdered metals give the cobalt maximal benefit, but are incredibly susceptible to breaking. The powder metal cobalt alloy demonstrates outstanding mechanical properties and cutting performance. Powder metal cobalt scissors are usually composed of a 50% Co (Cobalt) - 28.7% Fe (Iron) - 20% W (Tungsten) - 1.3% C (Carbon) alloy. These alloys attain an un-tempered maximum value of 66 to 67 Rc. Forged Cobalt tools are much tougher than sintered metals, but seldom have more than 10% cobalt in them, making them softer with Rockwells around 58Rc.

Rc (or Rockwell) is a term used to define hardness, the higher the number the harder the metal. Rockwell is simply a scale used to measure hardness. Hair scissors should have a minimum of 56 Rc to be a decent quality scissor. Ideal scissors have around 60 to 64 Rc.

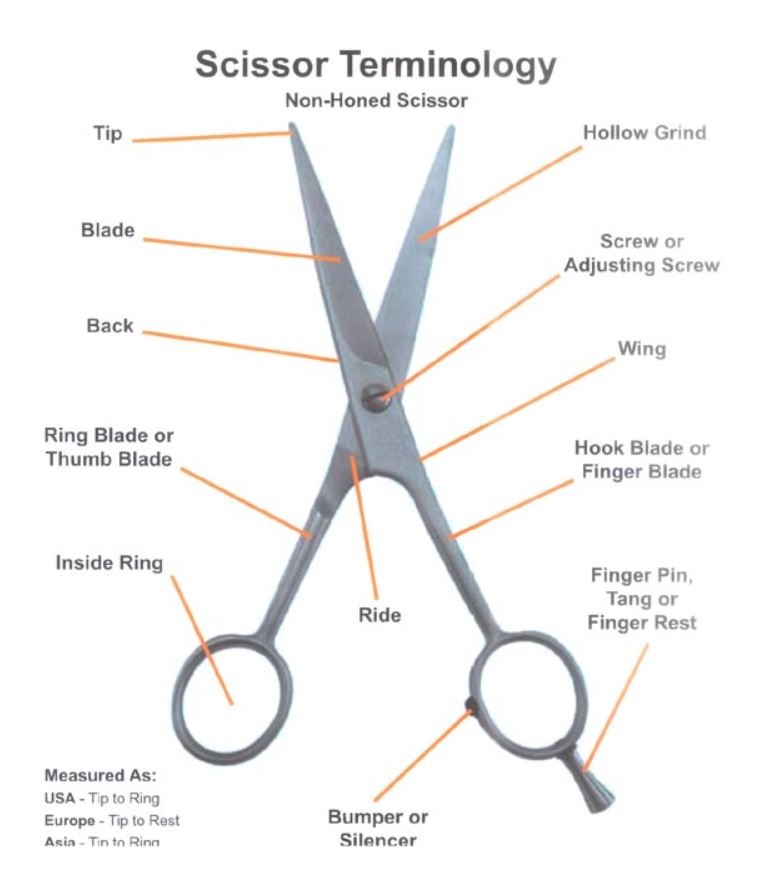

Below are illustrations showing the terminology used for honed and non-honed scissors.

As a professional groomer—especially in the show dog world—you already know that grooming is as much about precision as it is about care. Each season brings unique coat challenges, and your tools are your partners in meeting them. Whether you’re tackling a dense winter undercoat or refining a sleek summer trim, sharp scissors and well-tuned clipper blades make all the difference in both your results and the comfort of your canine clients.

In colder months, double-coated breeds grow a thick underlayer designed for insulation. While beautiful, this coat can be heavy, tangled, and resistant to dull blades.

Freshly sharpened scissors glide through dense fur without tugging, pulling, or creating uneven lines. For clippers, sharpening ensures the teeth work in perfect alignment, so you can thin bulk without overheating the blade or irritating the skin. This also means less strain on your hands and wrists, faster work, and smoother finishes on even the heaviest coats.

Warm weather calls for lighter trims that maintain a dog’s shape and coat health while preventing overheating. Crisp lines, clean edges, and precise shaping are only possible with blades that are perfectly honed. Whether you’re defining a poodle’s topknot or smoothing a setter’s feathering, sharp edges give you control over every cut. You get consistency from start to finish, with less time spent going over the same section to achieve the look you want.

Even if your grooming technique is flawless, dull scissors and clippers can cause unintended damage. Dull scissors and clippers can damage the coat, leaving split ends or fraying. They may pull fur instead of cut cleanly, leading to discomfort for the dog. It also increases grooming time leading to fatigue for both you and your furry client. In show grooming, these small differences can be the margin between a flawless silhouette and one that needs extra touch-ups.

Sharpening is more than just making a blade “cut again.” A professional sharpener:

By maintaining your tools seasonally—or more often if you groom daily—you’ll protect your investment and work more efficiently.

Consider aligning your sharpening schedule with the coat changes of your regular clients. For winter readiness, prepare for undercoat season with freshly sharpened heavy-duty tools. For summer, fine-tune blades for detailed trims and short, neat summer styles. For mid-year touch-ups, keep edges consistent for unexpected show dates or special events.

Your skills bring out the best in every dog’s coat. The right tools—kept at their peak through professional sharpening—ensure that nothing stands between your expertise and your vision. Whether it’s a lush winter undercoat or a streamlined summer trim, sharp and well-maintained blades are the foundation of every exceptional groom.

For anyone who relies on scissors or clipper blades—whether you’re a groomer, beautician, tailor, or anyone else who works with precision cutting tools—there comes a time when your trusted equipment doesn’t perform like it used to. The big question then is: should you repair it or replace it?

In most cases, regular sharpening and small repairs can dramatically extend the life of your tools for a fraction of the cost of buying new. Professional sharpening restores the original cutting edge, repairs minor nicks, and realigns moving parts so they work like new. Small adjustments or part replacements—such as springs, screws, or tension adjustments—are often inexpensive compared to replacing an entire pair of shears or a clipper blade.

That’s a big difference, especially if your tools are otherwise in good condition.

Common problems like dull edges, minor chips, loose screws, or uneven tension are quick and inexpensive repairs. Even small bends in scissor blades can often be corrected by a skilled sharpener.

If your clippers or shears feel rough, pull hair, or leave uneven lines, a tune-up might be all you need.

Surface rust or light corrosion often looks worse than it is. Many times, it can be polished away, restoring the tool’s performance and appearance.

However, if corrosion has pitted the metal deeply or eaten into the cutting edge, replacement might be the smarter or only option. A professional sharpener can assess whether the damage is purely cosmetic or if it affects function.

While repairs can breathe new life into many tools, replacement is the better choice if:

The best way to avoid premature replacement is to care for your tools daily and schedule regular professional maintenance. Visit our website for a more in-depth guide on caring for your blades, but here is a quick breakdown:

A little daily attention can extend your tool’s life by years—saving you money and frustration.

The choice between repair and replacement isn’t always clear-cut, but in many cases, a skilled sharpener can restore your tools to peak performance for a fraction of the cost of new equipment. By investing in regular maintenance and knowing when to repair versus replace, you’ll get the most out of every pair of shears and every clipper blade you own.

If it’s time for new gear, or your tools need expert attention, visit https://precisionsharpening.business/ to shop online—or stop by our in-person store to browse in person.

Dull edges or minor chips - Repair

Loose screws or poor tension - Repair

Surface rust or light corrosion - Repair

Minor bends in blades - Repair

Deep pitting or severe rust - Replace

Cracked handles or body - Replace

Blade worn too short/thin - Replace

Replacement parts unavailable - Replace

Premium shears are an investment—and like any high-performance tool, they require a different level of care than cheaper, mass-produced alternatives. Whether you’re working with Japanese honed-edge shears, high-carbon steel blades, or other high-end cutting tools, proper sharpening and upkeep are essential to preserving their precision, balance, and lifespan.

Brands such as Yasaka, Sensei, and other Japanese honed-edge shears are engineered with meticulous attention to edge geometry. Their convex edges are finely polished for buttery-smooth cutting, often allowing the blades to slice through hair or fabric with minimal pressure.

Unlike entry-level shears, these edges aren’t simply “sharpened” in the traditional sense—they’re honed to maintain the original factory angle and smoothness. An inexperienced sharpener can easily:

The result? A premium pair of shears that no longer performs like one.

While stainless steel is common in many shears, high-carbon steel is prized for its exceptional hardness and ability to hold a razor-sharp edge longer. This makes it ideal for high-precision work. However, the trade-off is that high-carbon steel is more prone to corrosion and requires attentive care. Regular cleaning, drying, and oiling are non-negotiable if you want to protect your investment.

Other blade materials you might encounter include:

With cheaper shears, sharpening often involves simply grinding a new edge at a standard angle. With premium honed-edge or convex shears, the process is delicate and precise:

Only a trained sharpener with experience in high-end shears should handle this process.

Your shears are your livelihood—treat them accordingly. Premium tools deserve premium care, and the right sharpening service will keep them performing like the day you bought them.

For expert honing of Japanese shears, high-carbon blades, and other specialty tools, trust a professional who understands their unique needs.

Choosing the right blade for the job isn’t just about speed—it’s about comfort for the animal, the quality of your finished work, and the longevity of your tools. Every coat texture, animal type, and grooming goal demands a thoughtful match of blade tooth count, steel grade, and bevel angle. Whether you’re prepping a show poodle, maintaining a barnyard dairy cow, or performing a medical clip, here’s how to pair the right blade to the right task.

Blade tooth count determines how close and smooth your cut will be.

The metal composition of your blade plays a huge role in edge retention, resistance to corrosion, and overall cutting feel.

The bevel angle determines cutting precision and smoothness.

| Animal / Coat Type | Purpose | Recommended Blade Setup |

|---|---|---|

| Poodles & Bichons | Show Grooming | High-tooth finishing blades, convex edge, high-carbon steel |

| Spaniels & Retrievers | Maintenance | Medium-tooth blades, beveled edge, stainless steel |

| Cattle | Show Prep | High-carbon or ceramic edge, finishing tooth, convex edge for detail areas |

| Cattle | Maintenance | Stainless steel, skip-tooth for bulk removal |

| Sheepdogs / Collies | De-matting | Skip-tooth, beveled edge, stainless steel |

| Veterinary Clips | Medical | Stainless steel, medium-tooth, beveled edge for durability |

The right blade choice means faster, smoother grooming, less stress for the animal, and less strain on your hands. Matching tooth count, steel grade, and bevel angle to the coat type and grooming goal ensures a professional finish every time.

For tips on how to recognize when your blade needs professional sharpening—and why keeping your blades honed reduces the risk of coat damage and skin irritation—visit our companion article: "When to Repair vs. Replace."

Whether you’re a seasoned sewist or just beginning your journey into the world of textiles, one truth remains constant: the right cutting tool makes all the difference. Using the wrong scissors or snips can lead to frayed edges, uneven cuts, and even damaged fabric. Below, we’ll compare fabric shears, pinking shears, embroidery scissors, thread scissors, and specialty snips—and help you match each to the right material, from sturdy quilting cotton to delicate lace.

Best for: Quilting cotton, upholstery fabric, denim, heavy canvas

Fabric shears are your go-to for clean, long cuts through woven fabrics. They typically have long blades (7–10 inches) and offset handles that keep the fabric flat on the table while cutting.

Best for: Quilting cotton, lightweight wools, unfinished seams

Pinking shears feature sawtooth blades that cut a zigzag edge, helping to reduce fraying on fabrics that are prone to unraveling.

Best for: Lace, applique work, intricate embroidery, delicate silks

Small and razor-sharp, embroidery scissors are designed for detail work. Their fine points can slip under tiny stitches or cut away excess threads without disturbing surrounding fibers.

Best for: Snipping loose threads, trimming seam tails Thread scissors (also called thread snips) are spring-loaded cutters that make quick work of stray threads.

Best for: Upholstery, heavy-duty fabrics, tight curves, or unique materials

Specialty snips come in many forms—spring-action shears for thick fabrics, duckbill applique scissors for trimming close to stitching, or micro-serrated shears for slippery fabrics like silk.

| Fabric Type | Best Cutting Tool |

|---|---|

| Quilting Cotton | Fabric shears, pinking shears |

| Upholstery | Heavy-duty fabric shears, specialty upholstery snips |

| Lace | Embroidery scissors |

| Delicate Silks | Micro-serrated specialty shears, embroidery scissors |

The right cutting tool isn’t just a luxury—it’s an essential investment in your craft. Matching the right blade to your fabric will improve precision, extend the life of your tools, and protect your materials. Keep your scissors sharp, store them well, and they’ll reward you with years of perfect cuts.