What is a Scissor and What is a Shear?

The word "scissor" comes from the Latin word "cisoria," meaning a cutting instrument, and the spelling is due to confusion with the Latin word "scissor," a form of the verb "scinder," meaning “to cut.” The word appears in Old French between 842-1300 A.D. as "cisoires," from which the Modern French word "Ciseaux" derives. In late Middle English, about 1400 A.D., there is found reference to "sisours" and "cysowres."

The word "shears" has quite a different derivation, originating from the Germanic/Teutonic root "Sker," which later changed to "Skeresa." In Old English, the word became "Scear." Currently in German, the word is "schere.”

Today's modern dictionaries define a scissor as "a cutting implement consisting of two blades joined by a swivel pin that allows the cutting edges to be opened and closed," while a shear is defined as "a pair of scissors" and "any of various implements or machines that cut with a scissor like action, often used in the plural".

German or Japanese: What's the Difference?

Japanese-style scissors have particularly sharp edges that taper to a point called a convex edge or honed scissor. These edges are very thin and sharp allowing the user to use all cutting techniques, including slide cuts, wisping, etc. Because the edges are so sharp, they would rub themselves dull on the hollow side of the edge. To prevent this, a hone line is ground in the hollow along the edge. The hone line is the thin flat line you see on the hollow side of the edge that runs from the tip of the scissor to the back. This gives the scissor a smooth and quiet run. Without the hone line, the scissor would run hard and loud.

The run is the feel and function of opening and closing a scissor. If a scissor sharpener does not sharpen and re-hone your scissor correctly, the scissor will never feel like it did when it was new. When sharpened correctly, the scissor often feels and cuts better than when it was new!

A German scissor has flatter edges than a convex scissor. This is called a sword or bevel edge. Bevel edges are not as angled as convexed edges, thus requiring one or both edges to be serrated or corrugated. Serrations are fine lines or teeth ground into the edge of one blade. The serration holds the hair, and prevents it from being pushed forward.

Because of its particularly sharp edges, the Japanese scissor (convex edge) cuts through hair smoothly and efficiently, with less force. The convex scissor is constructed for slide cutting or wisping. It runs smoothly, quietly, and lightly. However, it has the tendency to nick and dull faster than a bevel edge scissor and the tendency to push the hair more than a serrated, bevel edge scissor.

The German scissor (bevel edge) is very durable. It holds the hair well and does not push hair forward. It is the scissor of choice for blunt and layer cutting, dry cutting, and for cutting synthetic and coarse hair. However, due to the serration, it is unable to slide cut. It also runs louder and rougher than a convex scissor.

What Are the Most Important Aspects of a Scissor?

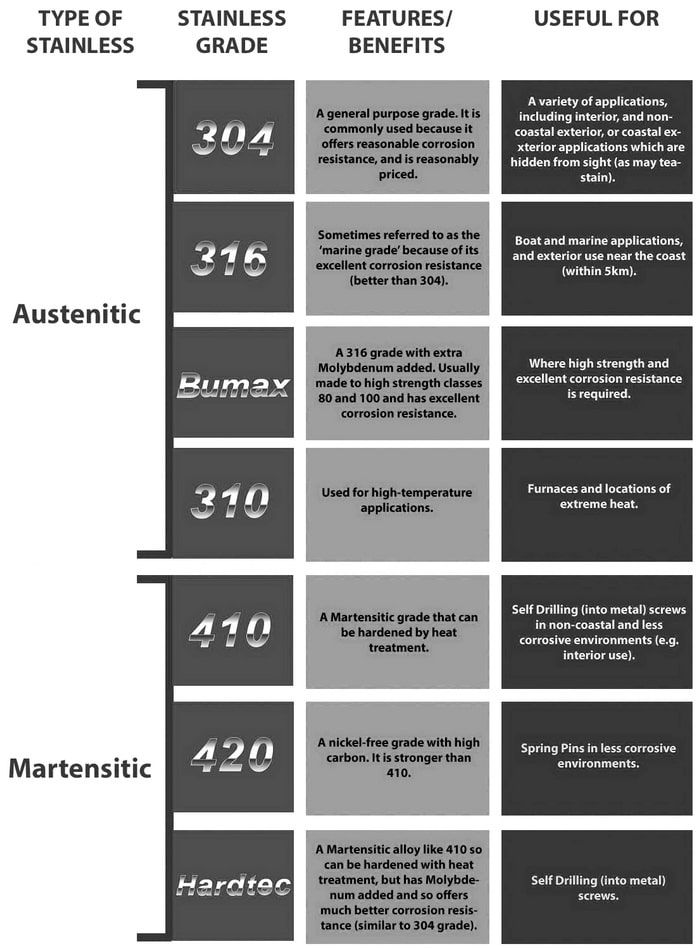

STEEL - What type of steel alloy the scissor is made from: What grade of steel is it? 300 series, 400 series, etc. This is the general metallurgical composition of the scissor.

PROCESS - The processing of this steel: Is it forged, cast, or sintered metal. Was it heat treated correctly, ice-tempered, etc.? Even the best steel can be useless in a scissor when processed poorly.

MANUFACTURE - The manufacture of the scissor: Is it convexed or beveled? Is it hollow ground? If so, is the edge angle correct, etc.?

What Does Ice Tempering Mean?

In the world of blades, the word "ice" is so popular that a lot of regular carbon steel scissors and shears claim to be ice-tempered, which does not technically make sense. Some even think "ice" is a brand name. The important thing to remember is that ice tempering is only beneficial on stainless steel.

In a simplified form, stainless steel is regular steel with chromium added to make the steel more rust resistant, thus "stainless" steel. The disadvantage of the high content of chromium in stainless steel is that the cutting edge dulls quicker. To overcome this, the steel is subjected to freezing temperatures to optimize the steel structure for hardness.

This is how it works: To make steel hard, it has to be heat treated. With stainless steel, that means heating the steel above 2000 degrees Fahrenheit. At that temperature the structure of the material is at its optimum. To preserve this structure, the steel is cooled rapidly (quenched) and tempered at about 450 degrees Fahrenheit. Now the steel has decent hardness and flexibility in the tool, but the chromium in the steel will not permit a long lasting cutting edge. To make the cutting edge last longer, the steel is subjected to around 120 degrees below zero; in other words, "ice-tempered". Without a steel analysis, it is virtually impossible to prove or disprove if ice tempering was done. The only other proof is how many cuts the scissor or shear can make before it dulls.

Hot Drop Forged vs. Cast vs. Blanked

For drop forged shears, pieces of steel are heated up red hot and put in a die, which is a mold that can withstand substantial pressure and looks somewhat like a cake pan in the shape of the shear or tool. Half of the form is fastened to a large anvil; the other half of the die is attached to the ram which acts like a hammer. The ram comes down on the steel, forging the pliable steel into the die and giving the steel the form of the future shear. These drop hammers are up to 20 feet high, standing on a 10-foot deep foundation. The ram can weigh 1000 lbs. or more. Because of variances in dimensions of the shears, some of the hot steel is being squeezed out of the die cavity. This creates a large burr which is cut off under heavy presses. The still hot-shear forgings are then cooled under controlled conditions to eliminate internal stress. They are then tempered and trimmed.

Molten metal poured into a mold that is formed to the desired shape is a cast shear. The casting process leaves the molecules of the metal in such a configuration that the metal becomes brittle and can be broken if dropped or if the sharpener tries to re-set the blade by bending. Cast scissors are harder and more durable than forged scissors but can break easily.

Most less expensive shears are blanked out. Strips of steel are cut out in the form of a shear, like rolled cookie dough is shaped with cookie cutters. The cheaper version of the "blanked" shears are then ground into shape. For a better quality, the cut out "blanks" are put into a powerful press and the blade is squeezed into shape, thereby making the steel near the edge compressed and creating a longer lasting cutting edge. This means that not all cheap shears are equally cheap. Drop forged tools and shears are far superior to blanked ones. The material flow of the hot metal being forged and pounded into the cavity gives the steel a much denser structure, better quality and ultimately longer life.

Cobalt scissors come in two types: Forged steel and powder or sintered metal. Powdered metals give the cobalt maximal benefit, but are incredibly susceptible to breaking. The powder metal cobalt alloy demonstrates outstanding mechanical properties and cutting performance. Powder metal cobalt scissors are usually composed of a 50% Co (Cobalt) - 28.7% Fe (Iron) - 20% W (Tungsten) - 1.3% C (Carbon) alloy. These alloys attain an un-tempered maximum value of 66 to 67 Rc. Forged Cobalt tools are much tougher than sintered metals, but seldom have more than 10% cobalt in them, making them softer with Rockwells around 58Rc.

Rc (or Rockwell) is a term used to define hardness, the higher the number the harder the metal. Rockwell is simply a scale used to measure hardness. Hair scissors should have a minimum of 56 Rc to be a decent quality scissor. Ideal scissors have around 60 to 64 Rc.

Scissor Terminology

Below are illustrations showing the terminology used for honed and non-honed scissors.